Wellhead Natural Gas Booster System

Wingoil Hydraulic Multiphase Transfer Booster Pump

$1.00

Product Introduction

Wellhead Natural Gas Booster System

---Wingoil Hydraulic Multiphase Transfer Pump

The Wellhead Natural Gas Booster System is an innovative and cost-efficient booster pump compression system designed by Wingoil, consisting of one automated intelligent hydraulic system, multiphase pumps, and power sources (electric power or natural gas generator), and/or gas lift unit. It can achieve the functions of mixed exploitation and transfer of gas, fluids and solids from wells, and is suitable for gas wells and oil-gas mixed wells, so we also call it Wingoil Hydraulic Multiphase Transfer Pump Unit.

The hydraulic multiphase transfer pump unit is an innovative and cost-efficient booster pump compression system, consisting of a automated intelligent hydraulic system, multiphase pumps, and power sources (electric power or natural gas generator), and/or gas lift unit. It can achieve the functions of mixed exploitation and transfer of gas, fluids and solids from wells, and is suitable for gas wells and oil-gas mixed wells.

It directly pumps oil, water, natural gas, and solids from wellhead into the pump system in between without three-phase separators. Through pumping, the pressure of the wellhead can be significantly reduced, which enlarges the pressure differential between the bottom hole and wellhead, thus improves the flow rate, gas production and liquid carrying capacity, achieving the goals of production stabilization and rising.

With continuous lowering of the liquid column height, the discharge of formation water accelerates, which extends the production period of the wells and enhances the exploiting rate of gas wells to a certain extent.

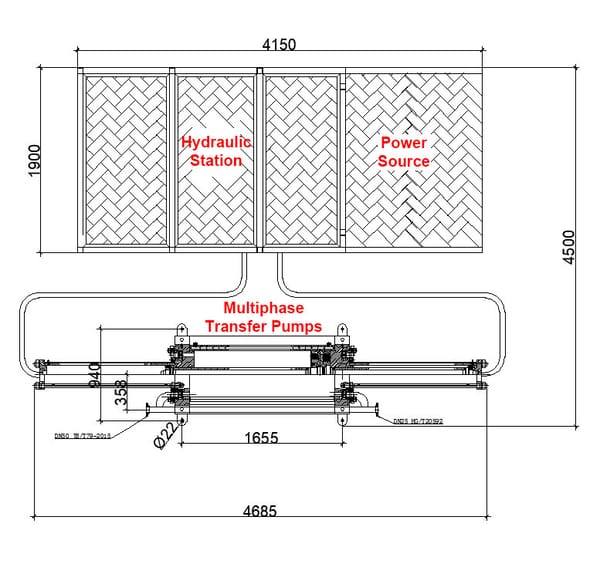

1. Structure of Hydraulic Multiphase Transfer Pump Unit

The hydraulic multiphase transfer pump unit mainly consists of three or four parts (as shown in the figure below):

1. Automated intelligent hydraulic system

2. Multiphase mixed transfer pumps,

3. Power source (electric power or natural gas generator)

4. and/or gas Lift Unit.

2. How does one Hydraulic multiphase Transfer Pump work?

The multiphase transfer pump is driven by hydraulic system and compressed by plunger featuring large cylinder diameter, long stroke and low stroke rate.

Cylinder diameter: 200-650mm

Stroke: up to 1000-2000mm

Stroke rate: 5-15 times/min

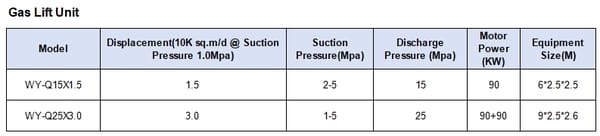

3. Gas Lift Unit Function

1. What function can a Gas Lift Unit achieve?

Directly compress the high-pressure natural gas from adjacent wells or in the main pipeline to 15-20MPa to achieve gas lift for low-yield wells.

2. What benefit we can get from the Gas Lift Unit?

Compared with nitrogen gas lift, it has the characteristics of low cost, low energy consumption, and low gas column pressure.

4. Advantages of Wingoil Multiphase Transfer Pump Unit

As proven by customer cases, our multiphase transfer pump offers the following advantages:

1. Reduces the wellhead pressure of gas wells or well clusters, increases output, and extends the production cycle of gas wells.

2. Enables mixed pumping and transportation of gas, liquid, and small amounts of solids without the need for three-phase separation. The inlet of the multiphase pump can be directly connected to the flowline, avoiding a pressure drop of approximately 0.2Mpa caused by three-phase separation.

3. Compared with lower efficiency of other kinds of pumps, its power consumption is about 50% lower based on the same gas production capacity and pressure differential.

4. Suitable for gas wells with wellhead of low pressure, as it can reduce the wellhead pressure to 0.1Mpa, as well as gas well clusters with high pressure wellhead and high output.

5. The hydraulic station system is controlled by PLC automation. It is intelligent and explosion-proof.

6. All sealed rings Long service life.

7. Integrates multiphase pump system and gas lift functions in one device, facilitating operations.

8. Skid-mounted structure for easy transportation and installation.

9. Uses self-produced natural gas from gas wells (clusters) as the gas lift medium, lowering gas extraction costs and significantly reduced power consumption. Suitable for single-well gas lift and well cluster circulation gas lift processes.

10. Equipped with remote control and monitoring system.

11. Short maintenance time and all maintenance can be done on-site.

12. Devices can be configured in series or parallel: multiple devices in series can increase output pressure; multiple devices in parallel can increase discharge flow.

13. Provides complete quality marks, reports, explosion-proof certificates, as well as various related equipment manuals, on-site work scheme, emergency response plans, and other relevant documents.

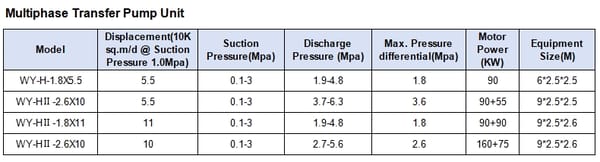

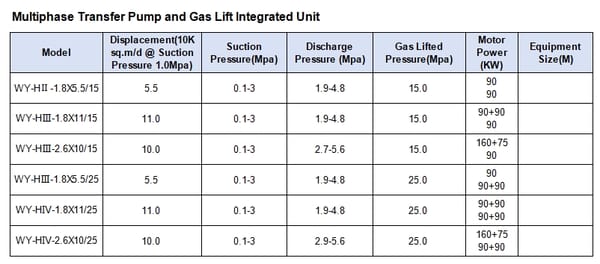

5. Product Technical Parameters

Remark: Specialized customization is acceptable based on the parameter requirements provided by customers.

6. Applications

The hydraulic multiphase transfer pump is mainly used in the middle and late production stages of gas well exploitation. After the high-yield flowing phase ends, the gas well output drops significantly compared to the initial stage, and the decline accelerates due to the back pressure from pipelines. There are multiple reasons for this, primarily the decreased gas storage in formation—especially, the reduced fluid flow rate in the near-wellbore area and increased liquid volume, which lead to lower gas well output and weakened water-carrying capacity of gas. This results in increased liquid accumulation in the wellbore and a higher liquid column, further impacting gas well production.

7. Practical Cases On-site